Technical characteristics

● Easy to operate, high precision, accurate and reliable measuring block verification system.

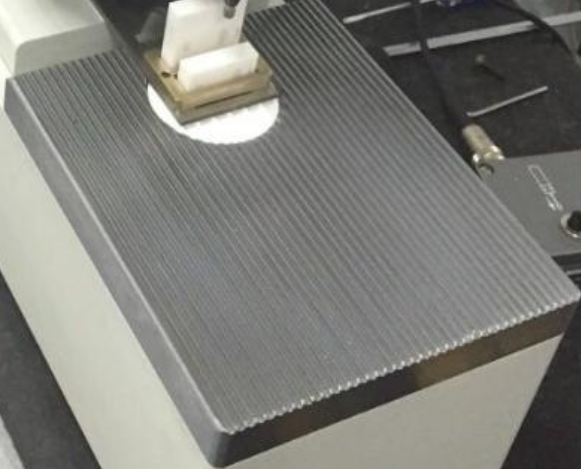

● High rigidity cast iron worktable to ensure stability.

● User-friendly structure design for users.

● High-precision grinding seven-bar workbench support frame, measuring block can be easily moved in the measuring table, and no scratches and wear on the measuring block working face.

● Equipped with a good insulation plexiglass protective cover, to ensure the temperature stability of measuring block verification.

● The measurement software is easy to operate, automatic data processing, can set the standard measure block correction value and customer information, directly generate the original record and certificate format, can automatically determine the level of measure block.

● Supporting measuring block positioning device and mobile technology, easily complete measuring block center point and display value detection.

|  |  |

Super large working platform Grinding table with steel bar, the surface of hard chrome plating after grinding, smooth surface effectively protect the surface of the measuring block does not wear, measuring block can be placed at a constant temperature, to ensure that the temperature difference between the measuring block and the table to keep the minimum, high hardness of the table, to ensure durability.

| Efficient 25mm absolute measuring range German HEIDENHAIN sensor can achieve 25mm measurement block directly, below 10mm measurement block with a standard block as standard parts, save time! The measuring force can be adjusted to 1N/1.25N/1.75N, and the motor controls the movement.

| Patented block fast moving device

The measuring block three-direction moving device can ensure the fast and accurate movement of measuring points of standard block and measured block!

|

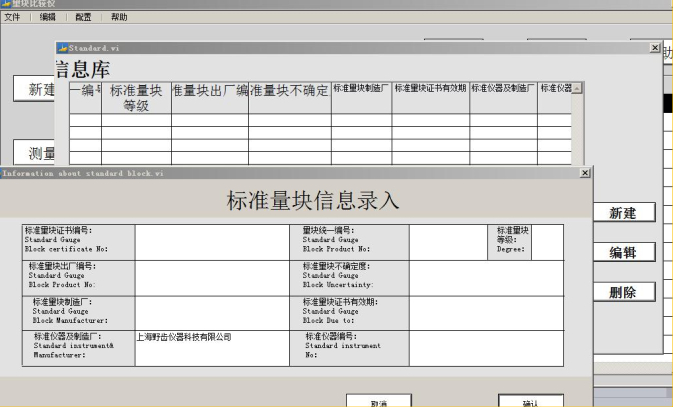

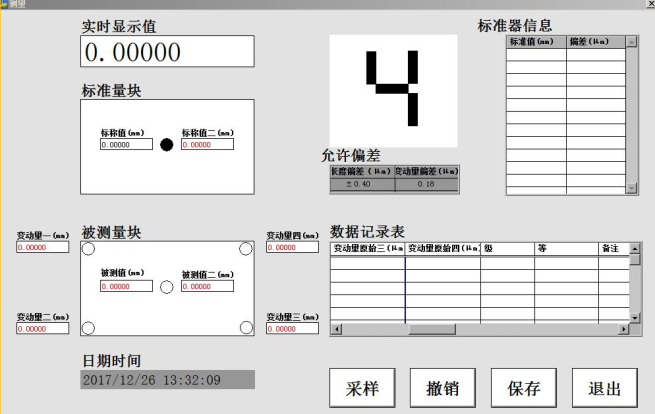

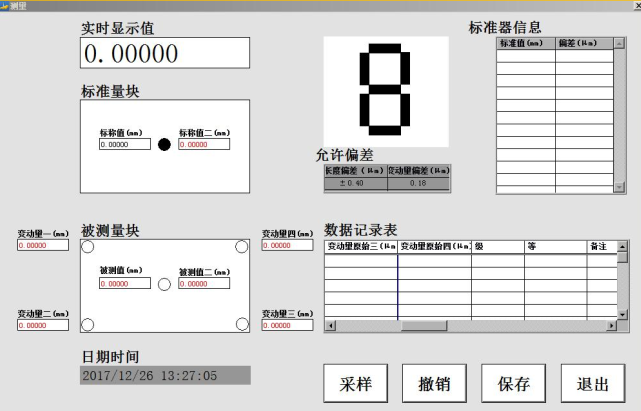

测量软件

|  |  |  |

| Standard measure block information input, the standard measure block information will be displayed in the original record after saving, input information after saving and then standard measure block traceability is worth input; Standard information input includes certificate number, standard block number, standard block manufacturer and other information. | The traceability value of the standard measuring block is input, and the standard value is automatically displayed for the value transfer when the measuring block is detected. The first column is the displayed value of the standard measure block, and the second column is the deviation value of the standard measure block. | After the standard input for the preservation, is measured in new pieces of information then test, test way can choose center measuring 'only' and 'length change detection', if only center of testing data, just four points detection, the software will jump out of the left interface test the gauge block, when moved to the small round black spots designated block gauge, The probe needs to be manually moved to the specified position for detection. | After the standard input for the preservation, is measured in new pieces of information then test, test way can choose center measuring 'only' and 'length change detection', if the test number length changes in content, there will be eight points need to detect, it will jump out of the picture on the right interface test the gauge block, when moved to the small round black spots designated block gauge, The probe needs to be manually moved to the specified position for detection. |