Main features:

● PLC can be connected

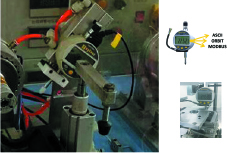

● resolution 0.001mm

● IP54 and IP67 waterproof and coolant

● new technologies for customizing menus

● function selection (min / max / difference, tolerance setting, preset value, etc.)

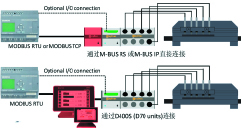

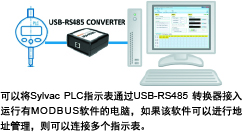

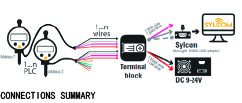

● PLC / RS232 (proximity) and RS485 connection

PLC features:

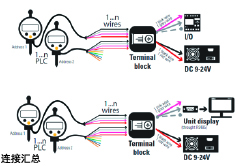

● all digital display meters have a unique address and are uniformly connected to one wiring terminal. The digital display meter and PLC are connected by pink and gray lines to realize collective communication.

● PLC requests data or sends instructions to the specified address (data request, preset, unit, resolution, zero, calibration date...)

● two way communication at the same time (e.g. data request, or preset to 20mm)

● the same instruction can be sent to all indicators at the same time, so excellent synchronization can be achieved in multi gauge applications. Hold (freeze) all values at time (t) ,(A+B+C for example)

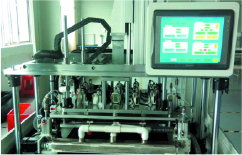

● PLC program fully automatic control of machine tool or measuring tooling

● SYLVAC data processor works in the same way as normal MBus.

● different gauge types can be mixed

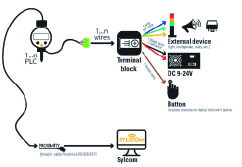

● automatic logic control can be created with the help of MB I / O module

● independent display control requirements for the site

● all digital display meters are powered by 9-24v power supply of external equipment (light, loudspeakers, relays...)

● the tolerance and preset value of each digital display meter shall be set separately

● output: the blue / Green / yellow signal line can light the three color alarm lamp according to the tolerance state.

● input: brown line is used for analog button switch control

● complete automatic control without PLC, PC and display