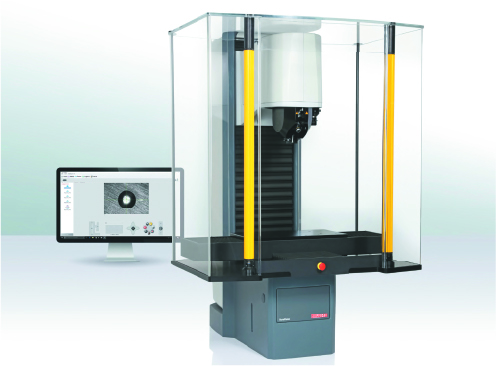

DuraVision 250/350 features:

● Fully automatic test eliminates operator influence

● Electric XYZ axis multi-test point automatic hardness measurement

● Test load 1-3000kGF

● Closed loop sensor loading technology, accurate and repeatable loadingSuitable for Brinell, Rockwell, Vickers and/or Knoop hardness tests

● Test test cycle and test method switch very fast

● Automatic switch between lens and press head

● 7-position automatic turret is optional

● Test indentation evaluation is to achieve the maximum repetition accuracy through automatic brightness and fast auto focus

● New autofocus ensures very fast focusing on the surface (patented)

● Automatic image evaluation ensures maximum repeatability and reproducibility

● High resolution camera

● LED lighting system provides uniform lighting intensity

● Automatic lighting adjustment, easy to perform hardness test on all surfaces automatic lens selection (optional multi-position automatic turret)

● Built-in 2-step zoom, plus optional additional 7-step zoom

● With the second camera (macro/panoramic camera), the user can select the starting point and test sequence with a few clicks of the mouse (optional)

● Ring lamp with dark field lighting, providing the best brinell hardness testing conditions for soft materials (optional)

● Unique custom templates simplify and automate repetitive testing tasks

● Automatic end quenching test for up to 9 samples (optional)

● Automatic execution of CHD, Rht and Nht test will automatically stop when the specified surface hardness limit is reachedMulti-sample software can be easily multi-sample automatic measurement test line programming (optional)

● Easy setup and test execution with PC operation, EcOS Workflow workflow-based software

● Data output, statistics and report functions include a variety of curve graphics display

● Easy to integrate database software interface

● CE cover protection to ensure operator safety (optional)

Panoramic camera positioning (optional) :

The panoramic camera has a minimum field of view range of 180x145mm and is equipped with 10x stepless zoom. It makes it very simple to locate single test points as well as complex test sequences and test templates in the real-time image of panoramic camera. With the unique panorama function, it is also possible to set up all test points in one operation and locate even larger sample sizes. Sample images taken from the Panorama camera can be inserted into test reports or archived on the company's web server.

One objective -- three magnification levels:

Intelligent interaction between the optical system and software, three-step zoom enables it to offer a wide range of magnification to meet a wide range of hardness testing needs while maintaining extremely high image quality standards. The unique three-step zoom is a standard feature throughout the Duravision G5 series.

Buchwald flat field intelligent light source system:

Smart light technology developed by EMco-test combines an objective lens with parallel light. Using this illumination, a parallel beam is guided by a mirror system and irradiated parallel to the test indentation. So the indentation is tested by light shining vertically from above to prevent shadow in the raised area, the outline is clearly discernible and the indentation can be accurately evaluated. Smart parallel light technology is integrated directly into the lens, requiring no adjustments or Settings by the operator.

XY platform: Linear motion large stroke electric XY platform is composed of two linear cross slide. This means that XY motion is divided into two independent systems for optimal automatic hardness testing, thus achieving optimal positioning with a high degree of positioning repeatability and accuracy.

XY platform: Linear motion large stroke electric XY platform is composed of two linear cross slide. This means that XY motion is divided into two independent systems for optimal automatic hardness testing, thus achieving optimal positioning with a high degree of positioning repeatability and accuracy.

Stepless adjustment of clamping pressure:

Based on the patented z-axis, according to the size and material of the sample, the best clamping force can be set by software stepless customization. Even complex specimens can be reliably tightened by selecting the appropriate clamping force.

Automatic turret:

DuraVision 250/350/450 can be equipped with 2-position rotary table or 7-position star turret; Multiple objective lens switches can be easily realized, and the built-in 2-step zoom improves the flexibility of the machine to an unprecedented level, allowing barrier-free testing of samples of various specifications.