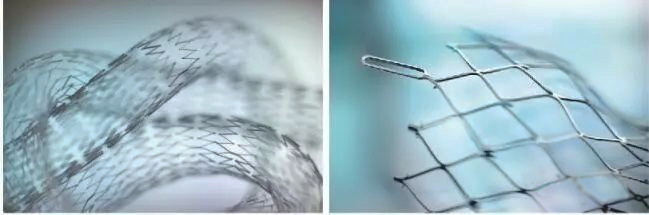

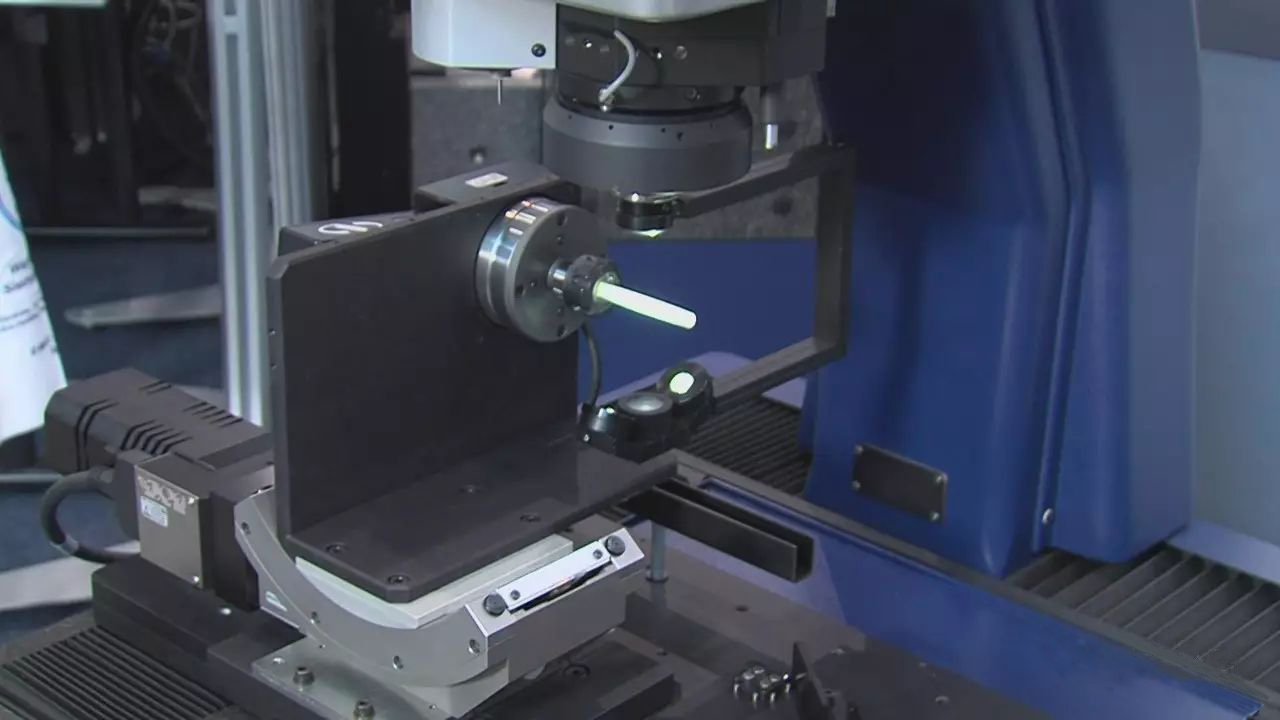

Application of multi-sensor technology in medical field: reliable measurement of vascular stents and other medical implants, high quality and high precision have always been very important to admedesschussler GmbH. As a pioneer in the field of medical implants, admedes must ensure that only products with high qualified rate can leave the factory. In terms of quality control, admedes relies on Werth's various measuring machines to strictly control the last quality. Werth measuring machine is a reliable and accurate measuring machine with minimal error due to its flexible use and high precision. Admedesschussler GmbH, a company based in Pforzheim, specializes in the manufacture of various vascular micro implants. The company's core product is the special nitinol vascular stent basically produced by the machine independently developed by admedes. Such nitinol implants have high requirements for the production process, with up to 15 production processes. Therefore, high precision and high quality play a decisive role in the molding of products. Such a stent will be implanted into the blood vessel by the catheter, which can reliably replace the blood vessel for a long time when the human body is injured, support the blood vessel wall and prevent the secondary formation of thrombosis. In most processes, the implant is laser cut, and a tubular blank made of nickel titanium is cut into a mesh structure. Dr. Andreas Schussler discovered the potential value of laser processing in his scientific research work in karlslu research laboratory, and established admedesschussler GmbH in 1996. In the first two years of the company's establishment, the admedes research team led by Dr. Schussler was mainly committed to the research and development of the process links of nickel titanium support manufacturing, so as to achieve the level of mass production, because the market expected the products directly processed, inspected and packaged by the supplier. Precision measurement, life-saving and healing main production processes: laser cutting, shaping and surface treatment. The products after laser cutting need to pass a cleaning procedure first, and then form a shape through heat treatment. Because NiTi is a memory alloy, even if the stent must be deformed and compressed when it passes through the blood vessel, the product will restore this shape. In order to reduce the rejection of human body, a layer of titanium dioxide will be formed on the surface of the scaffold through electrolytic polishing. This process ensures excellent human compatibility and material corrosion resistance. In addition to these three main processes, there are many other processes before the products are packaged and delivered to customers. Dirk heinig, a member of the management and one of the general product owners, explained: 'From the purchase of raw materials to the delivery, the quality control of products and production processes is very important. On this point, we are not vague. Quality control is the top priority of our attention. Every step is monitored by our online testing equipment, and all aspects and relevant requirements of each process are continuously and stably checked. An important part of quality control is the measurement of finished products Inspection of dimension, function and surface properties. Werth is the partner we are lucky to find. Their innovation ability and manufacturing ability are an excellent choice for us. ' Precision measurement, Left: vascular stents and other implants are fine structures cut by laser (the picture is part of the heart valve implant) both require high precision and high quality. Right: the nitinol vascular stent is the core product of admedes. The picture is from admedes. The multi-sensor technology makes the measurement highly flexible. The cooperation between admedes and Werth dates back to 2003. The then interaction leader found that Werth The multi-sensor technology and structure of the machine should be basically suitable for implant measurement. Through the upgrading and improvement of the existing measurement system, Werth can provide a more economical and flexible measurement scheme. He proved right. Although the Werth machine needs to be slightly modified in terms of clamping and lighting of vascular stents, technicians from both sides have conducted extensive tests with their technology and selected an excellent measurement scheme for this task. Dirkheining praised their cooperation with Werth: 'our joint R & D work closely connects us. In addition, our enterprise structure is also very similar. We all have innovative will and are committed to innovative R & D. Werth's existing technology is impressive.' The cooperation between the two enterprises continues to this day. With the support of admedes, the application scope of Werth CMM is extended to the field of vascular stent measurement. Admedes mainly uses Werth compound CMM in quality inspection. There are three models to serve this: videocheck, scopecheck and flatscope. As a partner for many years, admedes trusts Werth's technology and quality assurance. Its three videocheck and scopecheck are used for 'high precision dimensional measurement'. Accurate size and reliable measurement videocheck and scopecheck specifically measure the mesh width, angle and wall thickness of implants. Dirkheening values the current achievements in this regard, Because he is well aware of the past technology: 'before that, we must manually place the workpiece in the west of the optical microscope, take a picture and compare it with the corresponding drawing size, and then input the obtained data into Excel for inspection. We have to test thousands of implants every year, which is quite amazing.' Admedes uses werthvideocheck and scopecheck machines, which are equipped with image processing system on the one hand and contact detection system on the other hand. The image processing system is responsible for measuring the workpiece linewidth and finding out various features at the grid intersection. The lens can take these pictures and submit them to the measurement software to calculate the required data, which can be further evaluated. The contact measurement system can measure the wall thickness of the support. Therefore, all measurement data can be obtained by admedes with only one clamping. Werth's flatscope is used for functional tests that each implant must pass. For each test, the measuring machine is equipped with a special device to ensure that each measured workpiece reaches the human body temperature before measurement, and then measure its diameter and length. Only through such testing can admedes ensure that the size of the stent meets the medical requirements and is suitable for the site of human implantation. Precise measurement, life-saving economy and process technology, Werth measurement machine brings multiple benefits to admedes. For example, before that, admedes needed to pay high labor costs for 'accurate dimensional control'. In addition, Werth's videocheck and scopecheck machines make the measurement process more flexible and rapid. Multi sensor technology enables admedes to carry out a variety of special measurements on the workpiece on the same measuring machine, which previously had to be completed with the help of several different machines. Dirkheining especially praised one of the functions: 'for us, one of the excellent functions is the excellent auto focusing function of videocheck and scopecheck models. It can measure the Z direction at multiple heights without touching parts. Even non cylindrical parts have no problem.' Other advantages are reflected in accuracy and reliability. According to dirkheining, 'Werth's measuring machine has extremely high precision, and it has great advantages over other brands of measuring machines. In addition, he also pointed out that the manufacturing technology of precision vascular stents and other implants has made rapid progress, and the development of measuring technology should also be accelerated in this regard, because precision measurement is indispensable to precision manufacturing. And Werth is undoubtedly in a high-end position in this regard. I think Werth is in my position Our application field is indeed a market pioneer. Apart from Werth's machine, I have never seen such an accurate and reliable machine in precision dimension measurement. '