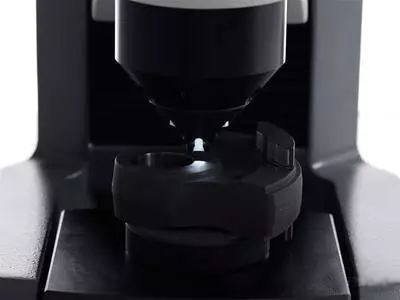

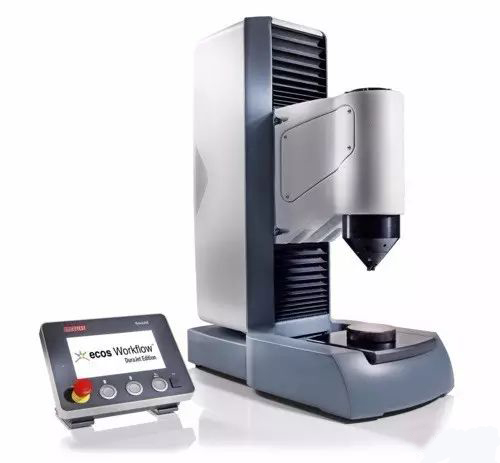

The fifth generation of Rockwell hardness tester is more beautiful and powerful! Due to the fifth generation electronic ballast technology and the test force of 1kgf-250kgf, durajet G5 has the ability to cover the whole Rockwell test force test. In addition, durajet G5 can also test plastic test and carbon test, as well as Brinell and Vickers depth test. Excellent flexibility and simple operation make durajet G5 an excellent Rockwell hardness tester on the market! Product features: the fifth generation of electronic ballast test force: the fifth generation of Rockwell hardness tester, more beauty and strength! The test force is accurately applied and continuously monitored; This prevents overshoot when placing the indenter and ensures vibration resistance. The entire test cycle is electronically controlled, thus ensuring high repeatability, independent of the operator. Working space lighting: the fifth generation of Rockwell hardness tester, fighting for beauty and strength! The LED lamp integrated into the nose cone illuminates the workspace around the measurement point, and the test point can be accurately placed even under gray lighting conditions. Full automatic test cycle: automatically start the measurement after pressing the workpiece. Once the measurement is completed, it will automatically trigger the release. This is particularly important in batch testing, saving valuable time! Fast mode provides a faster test cycle: this function reduces the time for application and release of test force by about 6 seconds. The hold time can be additionally set to 0.1 seconds to achieve extremely fast test time. However, the measurement using this function will no longer meet the standard. High standards: in addition to CE standards, durajet also meets high standards. Using high-quality components and materials, durajet meets the requirements of North America. (the control module is 'UL certified' and the plastic cover has high fire resistance rating) the fifth generation Rockwell hardness tester is more beautiful and powerful! Hardware interface: this interface allows the clamping and testing process to be controlled by the external system controller. This interface provides the integration of the hardness tester in the operation of unmanned automation solution. Data interface: the control panel has two USB ports (one on the front) is used to copy data on the USB memory stick, print reports or connect bar code scanners. The RJ45 interface allows durajet to connect to the network. Therefore, test data and reports can be saved on the network server. It is simple and easy to operate: only 3 steps, 1. Template; 2. Method; 3. Test data management: in the context of comprehensive quality assurance, Collecting a large amount of measurement data requires high accuracy and availability in computerized QA system. Therefore, the allocation of complete documents and measurement data to corresponding workpieces is particularly important. The export function integrated in ecosworkflow software provides a variety of report export requirements.