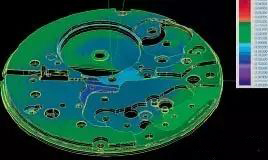

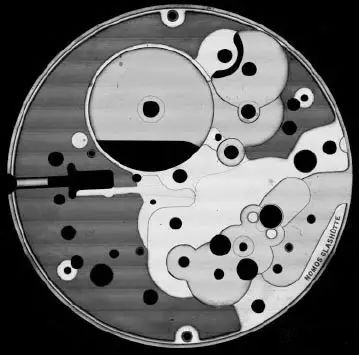

Linear chromatographic sensor - high precision at high speed Werth grandly launched a newly developed sensor series: linear chromatographic sensor for control 2017 (chromoticfocuslinesensor, CFL). It can quickly collect the geometry of the whole part. It can adapt to various application requirements by selecting different objective lenses and adjusting the measurement error and measurement range. Through the large axial measurement range, there is no need for controllable supplement for the part geometry. In order to quickly and large-area obtain the part geometry through scanning. For the surface, there are Parts with varying height can be scanned with 3D imitation. Linear chromatography sensor can be used to measure diffuse reflection, mirror and transparent parts, as well as the surface of parts with large inclination angle. CFL projects a row of about 200 white light spots on the part surface. The light reflected from the part surface will determine the distance between the sensor and the part surface through spectral analysis. Through the innovation of the new line sensor, the high-speed, high-precision and complete 3D data acquisition of parts is realized for the first time. One million measuring points can be measured in just three seconds. The line chromatography sensor also has another interesting function: the wavelength intensity of the reflected light is analyzed and evaluated, and a grid image of the part surface is created. Its subsequent analysis and evaluation allows to determine the part coordinate system or measure the geometric features 'in the image' through the image processing software. On this basis, due to the determination of position, various other sensors can be used for measurement without sensor conversion. At a fast measurement speed, the measurement accuracy of CFL allows the measurement of precision parts and micro features. The sensor can be used not only for the measurement of mirror or transparent parts such as stamping dies or cemented carbide and diamond tools, but also for the measurement of diffuse reflection plastic parts. The morphology of different surfaces is determined by high point density. For example, micro mechanical parts, watch dial. Another typical application of CFL is the coplanar measurement of LED arrays in the field of semiconductor technology. As the measurement result, the complete shape of the part surface is reflected in the form of point cloud, so as to measure flatness or roughness and geometric elements. The deviation between theoretical and actual values can also be displayed by color coding. Line chromatography sensor - high-precision line chromatography sensor at high speed. The measured point cloud data and the color coding deviation of CAD model show the grid image of line chromatography sensor - high-precision watch dial at high speed

The point cloud data measured by line chromatography sensor and the color coding deviation of CAD model are displayed

Raster image of watch dial