This application case was written in cooperation with Bosch. We once again thank Bosch for its support and trust in our project! (site: Linz, Austria)

Hardness tester requirements:

The purchase of this hardness tester is for the R & D department to highly automate the complex and wide hardness testing requirements. In addition, modern design and data management, and even related report output are also necessary! Durascan70 is equipped with fully automatic x workbench, electric Y / Z axis and 6-position turret. In addition to four objective lenses, Vickers and Knoop indenters are also installed in the turntable. It not only integrates auto focus and automatic evaluation functions, but also standardizes the operation evaluation of CHD, NHT and RHT in ecoworkflow software. Durascan 70 provides a panoramic camera to ensure faster boundary finding and test artifacts.

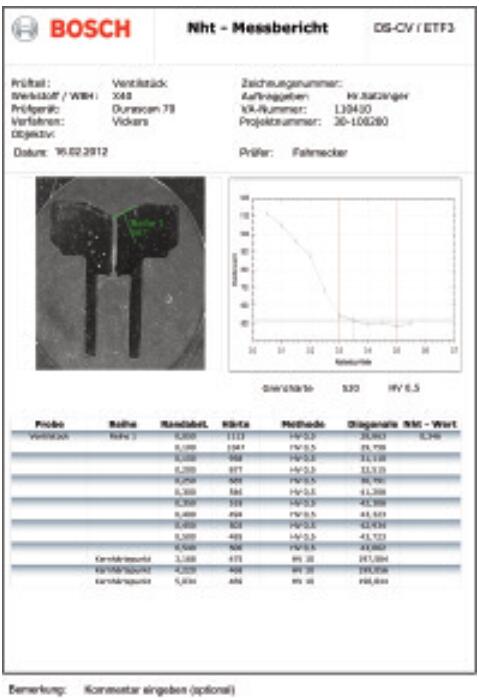

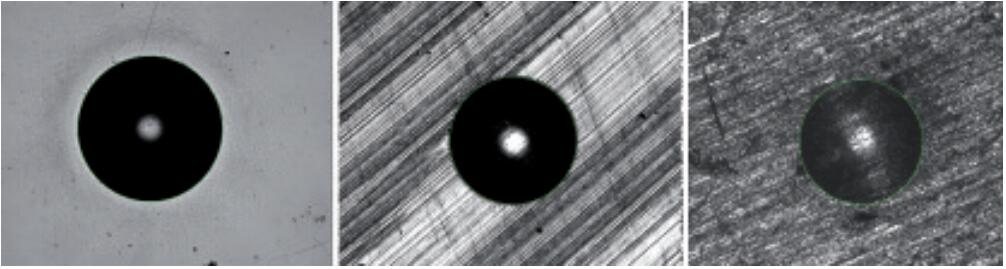

NHT hardness automatic test of valve plate_ Bosch Bosch_ Durascan70 test case and method: Test Method: conduct NHT series test on the valve plate. The hardness of sand core is increased by hv50, and the allowable boundary is 0.3 to 0.5mm. Test sequence: an operator generates a new sample or loads a created sample method according to the test method. According to the ecoswf principle, all required settings are set by the user. Ecoswf automatically evaluates the NHT hardness value through the defined core hardness points. The hardness penetration depth is evaluated by fully automatic leaving indentation image. The test can even be started directly in the view observed by the panoramic camera. Hardness penetration depth evaluation: the user creates a custom report and stores it directly on the company server. NHT value, boundary distance, graph, tester, etc. can also be displayed in the report. NHT hardness automatic test of valve plate_ Bosch Bosch_ Durascan 70 reliable quality assurance: due to the unique automatic focusing and automatic lighting control system, you can easily get accurate test results. (reduce user error)